BUNKER SOLID FUEL UTILISER

The new generation bunker disposer is a unit designed for efficient utilisation of solid waste: wood residues, municipal solid waste (MSW), peat and chicken manure. The unit does not require additional fuel: combustion is carried out by pyrolysis process and air supply by a powerful fan.

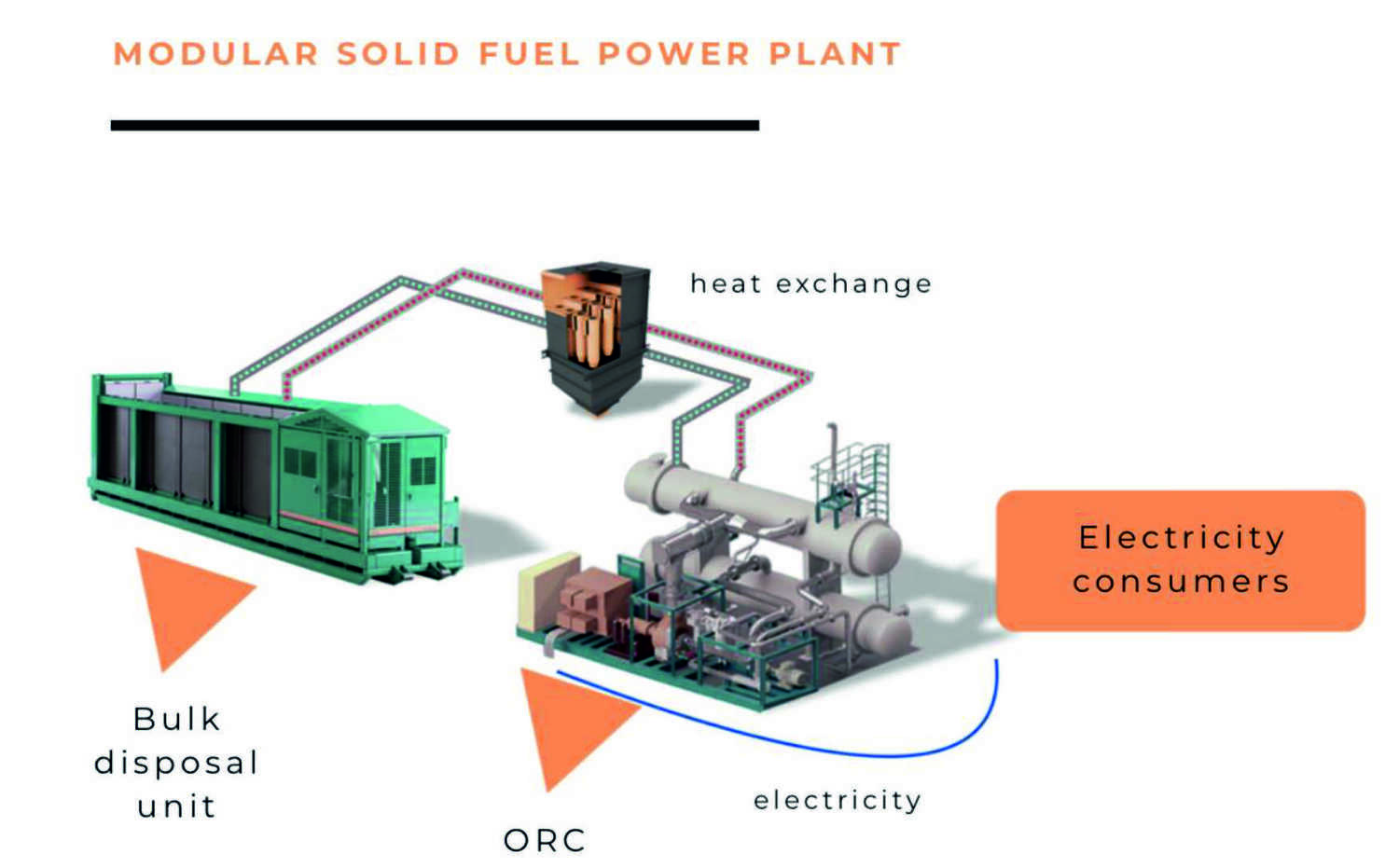

Principle of operation of the hopper disposer:

Inside the unit there is one main combustion chamber and five afterburning chambers where the secondary flue gases are completely burnt. Exhaust gases pass through a thermally expanded graphite (TIG) filter that effectively traps CO2 and other harmful compounds, ensuring environmentally friendly smoke and odour free operation.

Heat transfer to the ORC turbine circuit:

The hot flue gases are directed to a heat exchanger where their heat is transferred to the organic heat transfer medium (e.g. isopentane) used in the organic Rankine cycle (orc) circuit. The heated steam drives a turbine, generating electricity. Thus, the plant makes it possible to utilise waste and generate electrical energy at the same time.

The result:

Efficient waste utilisation with simultaneous electricity generation without the need for liquid or gas fuels. The system is suitable for remote and stand-alone facilities with solid fuel sources. The plant is easy to operate and requires only two operators. The configuration can be customised to suit the customer's requirements. The equipment comes with a 3 year warranty.

Benefits of the utiliser:

• Smokeless combustion without odour

• Does not require external fuel

• Supports combustion of various types of solid fuels

• High combustion temperature: 900-1400 °C

• Ash content - no more than 3-5 %

• Combustion rate - from 3 to 25 m3/h depending on the model Power supply - from 11 to 45 kW